I APOLOGIZE FOR MANY OF THE PHOTOS NOT SHOWING UP. Photobucket really screwed over a lot of people, I have to re-host them.

I was interviewed in the June 2016 issue of Road & Track Magazine discussing the 1991-1994 Nissan Sentra SE-R. You can read the article by CLICKING HERE

Nissan SR20VE & SR20DE motors / 1991-94 Nissan Sentra SE-R / 1995-98 Nissan 200SX SE-R / 1999-2002 Infiniti G20t mini-site

"The Last of the SE-Rs"

This mini-site is dedicated to the amazing 1991-1994

Nissan Sentra SE-R, 1991-1993 NX2000, 1995-1998 Nissan 200SX SE-R, the 1999-2002 Infiniti G20 and their fantastic SR20DE & SR20VE 2.0 liter motors. In my opinion, the SR20 motor is pound for pound, dollar for dollar one of the greatest motors in automotive history.

While I am of course an

avid music lover, singer, guitarist, pianist, and

songwriter, this is my second passion.

~ SCROLL DOWN FOR TONS OF SR20 INFO! ~

Click here for the actual website ----> www.JordanWhiteMusic.com <----Click here for the actual

website

Last Updated: 11.2.18

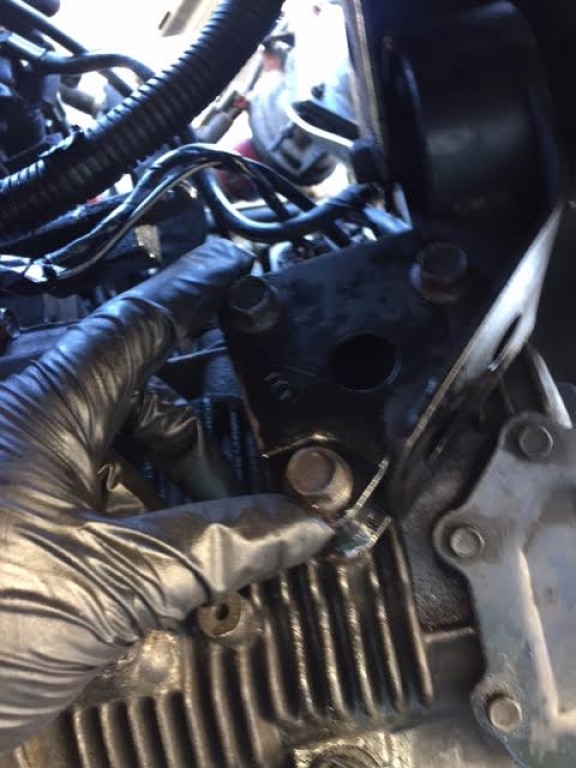

(the SR20VE motor and transmission, freshly pulled from the 1992 Sentra SE-R B13 chassis)

**CLICK HERE TO WATCH MY MOM'S REACTION TO THIS CAR ON HIDDEN CAMERA, quite funny:

https://www.youtube.com/watch?v=UiKZROwaFNs

2018: The 2000 Infiniti G20t (aka Nissan Primera):

Introducing my newest project, a very specific vehicle I have searched many years for. A P11 chassis Infiniti G20t w/ a manual transmission - nearly 80% of all G20s sold were automatic.

OVERVIEW OF THE INFINITI G20:-Infiniti stock/promotional photos of the 1991-1996 G20 (P10 chassis) and the 1999-2002 G20 (P11 chassis)

As you can see, the new G20, when unveiled in the summer of 1998, looked quite different and got a lot of people excited, especially in the automotive press. The edges were softened, and while it initially contained the same motor, the P11 came with bigger wheels, bigger brakes, a much improved interior, and more room. The press reviews were mostly positive, however the biggest complaint was the lackluster acceleration, as the 99-02 G20 is the *HEAVIEST* of all originally powered SR20 powered-cars ever sold in the United States, and it contained virtually the same motor as the lighter 91-96 model. It's a good 500lbs fatter than the '91-94 B13 Sentra SE-R & around 400lbs heavier than the B14 '95-98 200SX SE-R. This is due to many factors such as the extra sound proofing, full leather bucket seats, large sunroof, suspension components, powered & heated seats, longer & wider wheelbase, and many other things designed to give the appearance of and feel of "luxury" in the Infiniti product line. The version of the P11 Infiniti G20 in Europe & Japan is actually just called the Nissan Primera; it was offered with a few variants of the SR20VE motor, but as usual, in the United States, we got the shaft and it wasn't offered:

1999 Infiniti G20 base: SR20DE motor, no LSD trans. 140hp/132 ft-lbs torque.

1999 Infiniti G20t: same as above BUT w/ a limited slip differential (in the manual transmission models). The transmission is considerably stronger than the transmission that came in the '91-94 Sentra SE-R & the '95-98 200SX SE-R.

2000-2002 Infiniti G20t/G20 Sport: 145hp/136 ft-lbs torque w/ the newer "roller rocker" (RR) SR20DE motor (which was also used in the Nissan Sentra 2000-2001 SE model).

While the 1999 model is the easiest to swap motors in due to the ECU, the 2002 Sport model is arguably the best of them all, has the best interior, and the last year of it's production - but good luck finding a manual one. And in this car, a manual transmission is a *MUST* - the automatic transmission P11 G20, in stock form, all years, had 1/4 mile times in the upper 17 second range, which is absolutely horrendous, considering the stock B13 Sentra SE-R manual transmission could hit the quarter mile in 15.6 seconds and even the automatic was only about a second slower.

My G20t:

So if you have a keen eye, you probably noticed the SR20VE motor swap in the pictures above of my G20t. Thank the heavens above for this motor, because this motor makes it FEEL like it's supposed to be in there (and it WAS originally in there in Europe and Japan) - and it helps to equalize the major weight differences between it and other U.S. SR20 powered vehicles.

Even with the SR20VE motor (187hp, 144 ft-lbs torque) - an aftermarket 4-2-1 header, a 2.5 " Borla exhaust, a custom cold air intake, and a custom JWT ECU - the car still isn't all that fast. Don't get me wrong, it's "QUICK" but nothing like the B13 SE-R w/ SR20VE motor swap I had before. That car ran mid 13's in the 1/4 mile, this one I'd be happy to run high 14's. It's the WEIGHT - however one positive aspect of that is this is by FAR the smoothest and nicest riding SR20 powered vehicle I've ever had, and I've had over a dozen. All that extra sound deadening and ride-smoothing suspension makes a HUGE difference in ride quality, but you pay for it with slower acceleration.

Some Strengths & Weaknesses of the P11 G20:

(Infiniti stock/promotional photo of the '02 G20 Sport model)

So I have officially been a G20 owner for over six months now, and I have really gotten to know the car inside and out, just as I did with all my prior SR20 powered cars. I admit I never actually expected to find a G20 in such good condition *AND* w/ manual transmission, that I had sort of given up. Given up just like I have in trying to find a clean 1993 Nissan NX2000 T-Tops, because they're all either junked, modified to death, or destroyed. Every month, every week, hell - every DAY that goes by, these amazing cars go to the death yards and are crushed. Had I been older in 1996, I could have found any type w/ any combination of options I wanted. But alas, I wasn't even driving yet when these cars were fresh & new.

The 2002 G20t manual transmission, the car's final year of production, is the model I wanted the most. It has the best interior, upgraded styling, and certain things were tweaked for the better. The interior in my opinion is simple perfection:

(Infiniti stock/promotion photo of the interior of a '02 Infiniti G20 Sport)

(Infiniti stock/promotion photo of the interior of a '02 Infiniti G20 Sport)For the 2002 "Sport" model, Infiniti introduced a better looking front grille, completely changed the interior by re-doing the leather seats and inner door trim to look "less 90's" and added white face gauges. You can view the 2002 Infiniti G20 official press release by clicking

HERE. I couldn't find any 2002 Sport models for sale except for those with an automatic transmission here or there. I thought about purchasing one and then doing a manual transmission conversion, but the cost, time, and practicality just wasn't worth it. It would be easier just to swap over the upgraded parts to my earlier model. So I'm still looking for a 2002 Sport donor car to do so.

My 2000 Infiniti G20t modifications:

Motor:SR20VE motor swap

SR16VE N1 camshafts

Custom cold-air intakeeBay 4-2-1 header

G-Spec lightweight water pump pulley

JWT ECU (tuned for 91+ octane fuel, Nissan Maxima MAF) 333cc fuel injectors

Borla 2.5" cat-back exhaust

Walbro 255LPH fuel pump

MSD 8969 window switch (controls VVL activation)

Nismo 1.3 bar radiator cap

OBDLink MX Bluetooth scan tool

Transmission:

5-speed manual w/ viscous limited slip differential

Fidanza lightweight flywheel

OEM clutch

Suspension:

TEIN adjustable coilovers

Front strut tower brace

Rear strut tower brace

MOOG front sway bar bushings & end links

Brakes:

Fronts: Power Stop cross drilled/slotted rotors w/ Z26 carbon pads

Rears: Cross drilled/slotted rotors w/ OEM pads

Tires:

New 205/50/15 Nitto Neo Gen tires (good for the track)

Cosmetic:

JDM Primera headlights

JDM Primera front corner lights

JDM Primera clear side markers

JDM Primera white-face gauge cluster

JDM Primera grille/trunk badging

Sylvania Silver Star headlight bulbs

'02 Sport grille

'02 Sport inner door sills

AVS sunroof deflector

I

replaced all the broken parts when I first got the vehicle (it needed a

new wheel, all new struts, new brakes, tie rods, a new windshield etc.)

I took care of those things and now am starting to modify it more for

power. The very next performance modifications should definitely be the

N1 cams paired with Supertech valve springs - this setup can increase

power output in this motor a good 25-30 WHP - but they are are not

cheap. With the cams and springs upgrade, I would expect this motor to

make around 195-200WHP instead of the 175~ish it's probably making

now. And when weight is a factor, every extra HP you can free up makes a

difference - besides gutting the interior :) Other potential

modifications down the line are lightweight pulleys (crank & water

pump) - a better header design (4-1 designs make more power over

current/cheaper 4-2-1 design) - and upgraded throttle bodies.

JDM clear side-markers:

These are not a direct fit, you either need to rewire the new pigtails or modify the inner plastic to fit flush in US models. These give the G20 a much cleaner look than the murky orange colored ones. They can be purchased online for as little as $25:

(Left to right: a comparison of the original side marker and clear marker, the new JDM clear markers, and one installed on the car)

The "Cold Weather Package" Modification:

The interior of my G20t is all black leather, which looks great - but is not always great in extreme temperatures. In the summer they can get too hot, in the winter they can be freezing cold. While we can't do much about the summer, we can do something about the winter. The '99-02 G20 had a factory option from Infiniti known as the "cold weather package" - which was really just heated front seats and heated side view mirrors. All G20's have the location where the switches are, but if you didn't get the "cold weather package" there are just plastic squares where the switches would have been.

This is another reason why the P11 G20 is so much heavier than the other SR20 powered cars- all of these options - but in the spirit of the "what the hell" effect in human psychology I decided to do it anyway. I see no reason to bother with heating the mirrors as I've never needed that in any vehicle before, so I'm just going to do the heated seats. For this you need three things:

1) The toggle switches

2) The wiring

3) The heating element

To get these items, rather than spend a fortune directly at the Infiniti dealer, just go to one of your local pull yards and look for any 1999~ish to 2005 Nissan or Infinitis with heated seats. The heated seat switches in the P11 G20 are actually the same in all Nissan & Infiniti models of similar years - in fact, the switches I procured in the photo below came from a 2002 Nissan Pathfinder! So for a few dollars at the pull yard, they were mine. Be sure to get as much of the wiring as possible:

(Heated seat switches from a '02 Nissan Pathfinder, exactly the same as the P11 G20)

Now the harder part is locating the heated seat elements. They are harder to find as some of the larger Nissan/Infiniti SUV elements are too large for the smaller G20 seats. So your best bet is to find the heated seat element from another actual G20. I am still in the process of doing that, so more on that later. :)

THE SR16VE N1 CAM INSTALLATION!!

SOOOO.... the N1 camshafts (above) have been installed in the G20t!!

..with a couple minor hiccups as usual. Plenty of photos and detailed information to come. Overall, installing camshafts in the SR20VE motor was very similar to installing them in the SR20DE motor, except a few minor details (hint: it's a little bit more difficult). So far I can tell you guys that I am LOVING the extra power and bigger/fatter sound of the cams engaging. I am also experimenting with the MSD window switch by changing the RPM at which VVL engages at. At first it seemed 5200RPM was the best, but then it appeared as if 5600RPM, to as high as 5800RPM was even better. The only way to truly determine "the sweet spot" is to take the vehicle to a dyno, as every motor is different depending on other modifications.

I went on the SR20 Facebook forum and asked others SE-R owners who have installed N1 cams in their SR20VE motors what the optimal RPM is to set the VVL crossover was. I was shocked to receive responses of anywhere from 4600RPM to 6200RPM! So who knows. Will find out soon.

The N1 cam (left) vs the OEM cam (right). Notice how much larger the biggest lobes are on the left cam (even the smaller lobes are noticeably different).

The 1998 Nissan 200SX SE-R: Last of the TRUE SE-R's

Table of Contents from here and below:

A) Overview

B) Mitch Piper roll cage

C) Future goals

D) Hotshot Header install & notes

E) Semi-cold air intake

F) 1997 bumper conversion

G) Manzo front strut tower brace

H) F1 Motorsports rear strut tower brace

I) Replacing the clutch cable

J) JWT S3 camshafts tutorial & install

K) "eBay" header comparison

L) Stromung cat-back exhaust

M) NX2000 brake upgrade (AD22VF)

N) Replacing the rear brake pads

O) Stainless steel brake lines

P) Re-installing A/C

Q) Installing a new clutch in the '98 200SX SE-R

R) ES suspension shifter bushing install & notes

S) Waxing the SE-R

T) The SR20VE motor & more

Jordan White's SR20VE/SR20DE Mini-SiteAfter a weekend of hanging out with my brother and riding around in his 1993 MR2 turbo in July, I decided that boost was the way to go. I sold the SR20VE motor, transmission and shell of my 1992 Sentra SE-R. I still dearly love the SR20VE but in terms of cost effectiveness and power, forced induction makes more sense. Staying naturally aspirated, I had hit a power "wall" with the SR20VE. That motor was an NA beast with almost every modification and there wasn't much more to do to extract additional power. The car, with moderate weight reduction, ran consistent low 13's in the 1/4 mile on regular street tires. I'm pretty confident with slicks it could have been in the 12's....but anyways, a midst many changes in my personal life in the late summer and fall of 2014, I decided to get a '98 200SX SE-R for my next project.

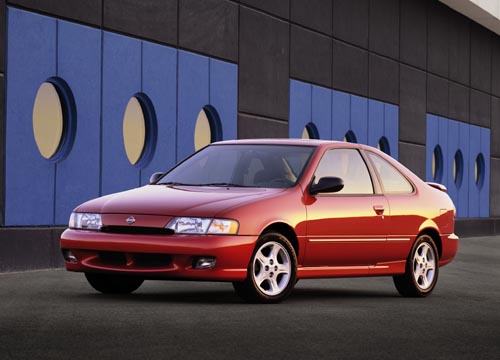

(Stock photo of a 1998 200SX SE-R from Nissan)

Nissan 200SX SE-R (B14 chassis) overview:

Debuting in 1995, the Nissan 200SX (B14 chassis code) came in two different trim levels during its run. The base SE model came with an economy based 1.6 liter 115HP 4-cylinder, known as the GA16DE, with rear drum brakes, smaller wheels and conservative styling. The second was the SE-R model, which included the infamous 2.0 liter 140HP 4-cylinder SR20DE, quite similar to the SR20 standard in the 1991-1994 Sentra SE-R except for some minor changes (the benefits and disadvantages of those changes are still hotly debated in the SE-R community to this day!)

The SE-R model came standard with a viscous limited slip differential transmission, a leather wrapped steering wheel, 4-wheel disc brakes, more aggressive styling and other upgrades. The 200SX became controversial due to the

state of California banning the sale of them within it's borders in 1997 due to

emissions concerns. Nissan responded the following year by putting even more

emissions related components on the vehicle; and perhaps to offset for extra

costs"deleted" the previous limited slip differential (LSD) equipped

transmission that had been standard on all USDM Sentra/200sx SE-R's since 1991.

Now, if you're going to race a FWD vehicle on the track, LSD is basically a

must. Luckily for owners of the 1998 models this is easily remedied by swapping

in the LSD transmission from a 2000-2001 Sentra SE (which also came with the

SR20 motor although in the B15 code chassis) as the B15 transmission is stronger. You can also swap in any 91-97 SR20 powered car 5-speed transmission for the LSD.

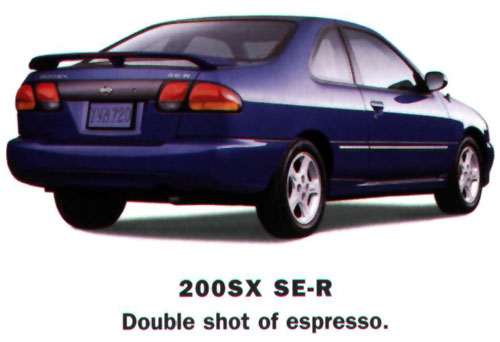

(Original Nissan magazine ad)

- Motor: As I eluded to above, Nissan claims the horsepower &

torque stayed the same for all 1991-1999 SR20DE powered vehicles, but it's clear to

most that the 200SX SE-R does not have the same power as the original Sentra SE-R, at

least from the factory. Many blame the newer intake manifold design of the post

1994~ish SR20DE motors and the less aggressive intake camshaft (in fact a

popular and cheap modification is finding a used intake camshaft from a

1991-1993 Sentra SE-R and installing in the 1995-1998 200SX SE-R motor). Some

say it's more like the Sentra SE-R should have been rated closer to 150HP. Who

knows. Both motors have their merits. Neither compares to the SR20VE motor

(190HP+) in stock form, but with the right modifications, or of course turbo

charging, the can be just as powerful as it's SR20VE cousin. Also, ECU

programming is less aggressive in the 1998 models than the 1995-1997 models as

well.

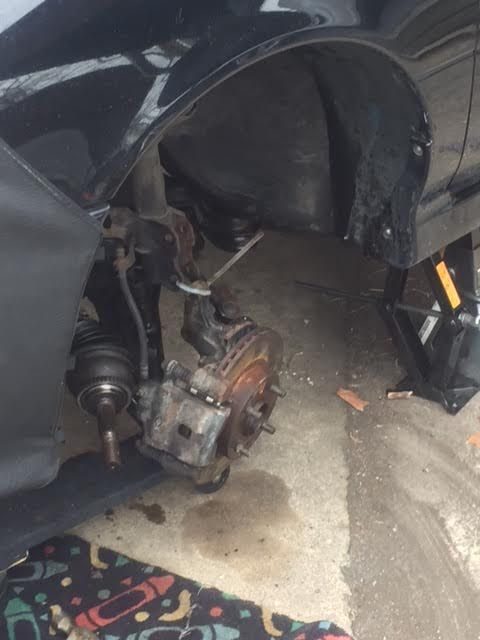

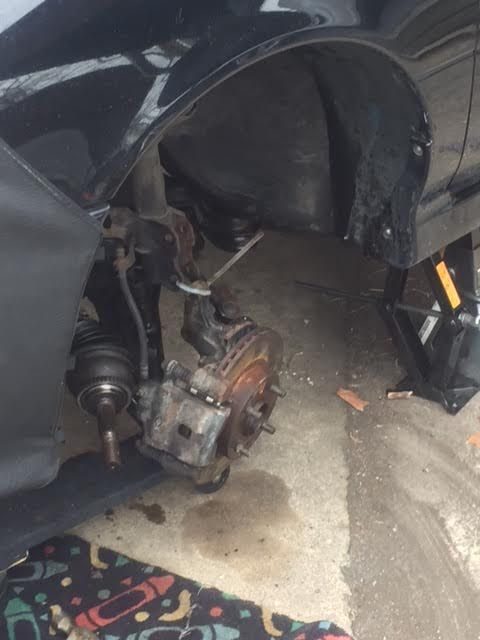

Suspension: A Homer Simpson "DOH!" is quite appropriate here for what Nissan changed in the suspension department from the B13 to the B14 chassis. While the

'91-'94 Sentra SE-R and the '95-'98 200SX SE-R share virtually the same front end suspension,

the rears are completely different. Instead of of an independent rear system like the B13, Nissan instead went with a freaking beam:

Ignore the WD40 grease spots all over the place, I was changing my brakes at the above photo was taken. So anyways, a beam linking both rear wheels is not ideal for high

performance & competitive driving. There are some methods the SE-R community

employs to improve this (having the "beam" slightly bent is one) however assuming

both vehicles are virtually identical in setups and tire selection the B13 SE-R

should out handle the B14 SE-R with equally skilled drivers. There's also a

significant lack of suspension travel which forces many to trim/cut the

bump-stops. If you install lowering springs in your B14 (and the B13 too

although it's not as bad) that decrease the chassis height by more than

around 1.6" inches you will actually experience worse handling than while riding on stock

suspension. If you see any Sentras or 200SXs driving around your town "slammed" or "stanced" - well, it may look sporty, but they will actually handle and perform worse! Especially in the

northern states with the potholes that develop from road salt and such.

Transmission: Besides LSD being omitted in the

1998 models the transmission is nearly identical, however there are some

benefits to the B14. The "5th gear popout" problem that plagued the

B13 SE-R (especially the '91-'92 models - it happened to me) was addressed by Nissan and eliminated by redesigning the 5th gear input shaft. There is some

evidence to suggest the B14 transmission/gearbox is a bit stronger than the B13

but this is also debatable.

Styling/Interior: This topic is of course very

subjective. There are many people who absolutely love the European-styling of

the B13 SE-R (similar to the BMW E36 M3) and there are those who prefer the more

modern looking B14 SE-R. Both are two door FWD "sporty" coupes and I feel both

look better or worse than the other dependent on the angle of the photo and the

condition. I have owned three B14's, a '97 200SX SE-R, a '98 Sentra SE (four

door version with the SR20DE motor) and a '99 Sentra SE-Limited. All B14 SE-Rs came standard with power windows,

power locks, cruise control, dual airbags, a CD player, and key-less

entry. Besides airbags which have an obvious safety merit, some in the SE-R community prefer

the simpler nature of the B13 SE-R, with it's roll up windows; some did

not even have cruise control, airbags only became available in the 1993+ model

year. Of course these factors were a sign of the times; in 1991 very few

vehicles except those on the higher end came equipped w/ power windows and

locks, but by 1996 all vehicles in the U.S. were required to be equipped w/

airbags in the front. All this equipment helped to make the B14 SE-R fairly

heavier than the B13 SE-R, and when you factor in a possibly weaker motor it's

easy to see why many prefer the B13 SE-R. Strangely, Nissan decided to make

both the speedometer and tachometer white in the '98 SE-R & '98-'99 Sentra

SE, but left the fuel and temperature gauges black like the previous years

models. No one really knows why.

My 1998 200SX SE-R

In fall of 2014 after selling my 1992 Sentra SE-R, I picked up a near mint super-black 1998 Nissan 200SX SE-R (actual photos above) from a friend in Maryland. Thanks to Charles for driving us down! The car was in fantastic shape and has some modifications that address the issues I touched on above including parts that will be needed in the future to handle boost.

Current Modifications (as of December 2016):

Motor: JWT S3 camshafts, custom cold air intake, eBay 4-2-1 header, Stromung 2.5" cat-back exhaust, high flow catalytic converter, Infiniti G20 ECU, Walbro 255LPH fuel pump

Transmission/Driveline: 2001 B15 Sentra SE transmission & gearbox w/ LSD, Clutchmasters FX500 6-puck clutch & pressure plate, Fidanza lightweight flywheel, B&M short shifter, ES pro-thane shifter stabilizer bushing, Place Racing transmission motor mount

Suspension/Safety: MANZO front strut tower brace, F1 rear strut tower brace, Mitch Piper Motorsports custom 4-point rear roll cage

Brakes: Nissan NX2000 BABK (big ass brake kit) ceramic pads front & back, rear stainless steel brake lines

Wheels/Tires: 16" Konig wheels w/ directional & grippy 205/45/16 tires

Other: Block tapped for turbo, B13 Sentra SE-R front seats, Odyssey high-performance battery w/ Summit battery relocation kit, XScorpion distribution block, JVC CD/MP3 player w/ front & rear speakers & remote

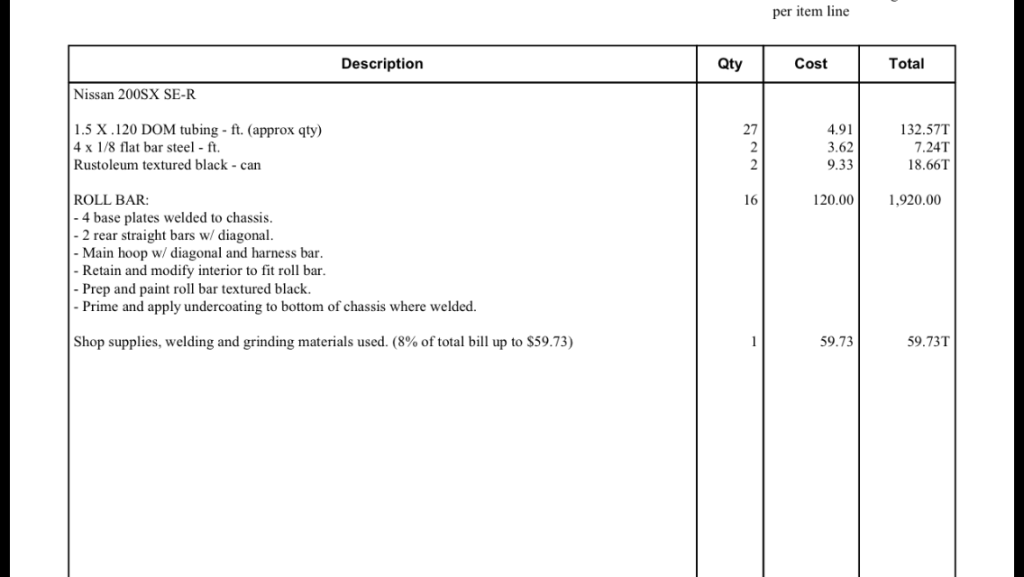

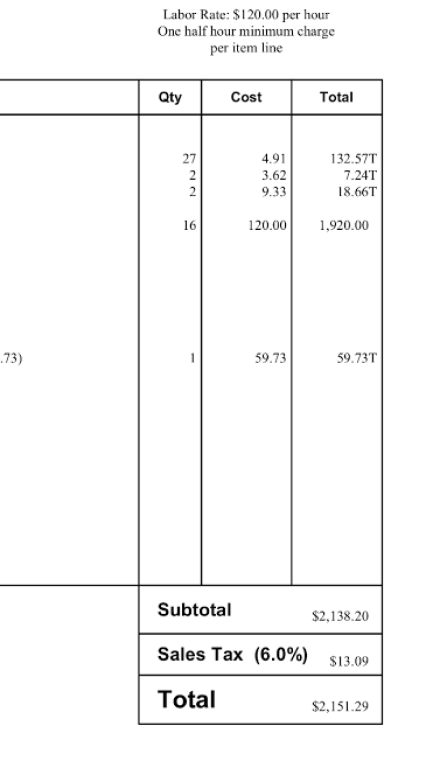

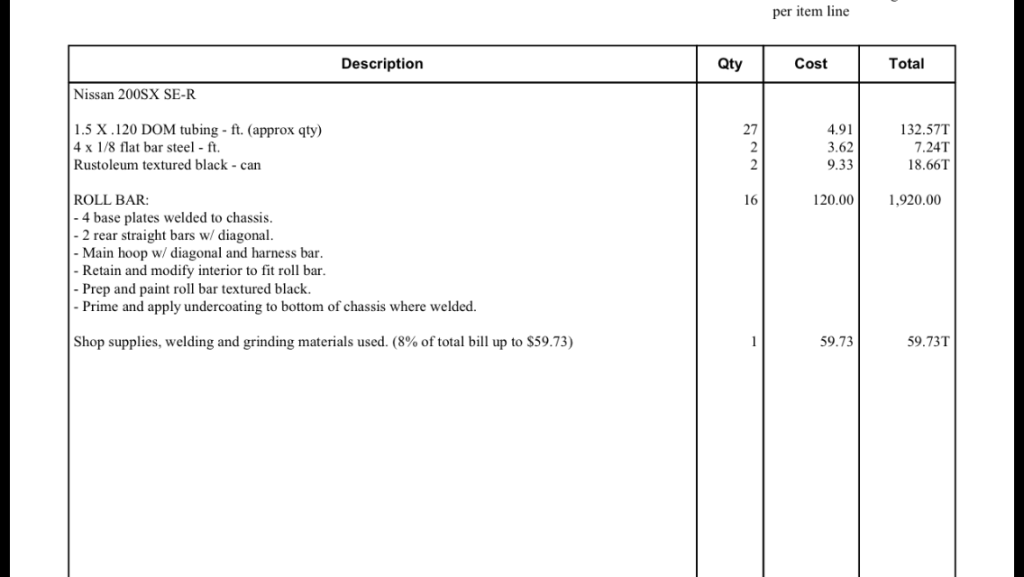

The Mitch Pipe roll cage:

I have a custom rear roll cage installed by Mitch Piper Motorsports whom specialize in custom automotive safety components. If you are interested you can learn more about their roll cages HERE.

I will be up front about having a roll cage in a street car:

It's actually more dangerous to have a full (front & rear) roll cage in a street car than to not. Why? On the track you are wearing a helmet and in the event of a collision your head will be protected by the helmet if it hits the cage. In a street car or even daily driver you are not wearing a helmet, leaving your head susceptible to slamming into the bars in the event of an accident. The bar is made of steel, and why I only have the cage in the REAR. It's sort of a compromise between the helmet issue and not having a cage at all. The bars are no where near the driver or front passenger areas, however I am well protected in the event of being rear-ended, and semi-protected in a roll over.

As these photos show, I have lost use of the backseats but the cage not only makes the vehicle safer in the event of a collision (assuming there are no passengers in the rear) but also increases structural rigidity. Quality roll cages are welded directly to the frame and act similar to a strut tower brace by reducing chassis flex during hard cornering.

These photos show two locations where the cage is welded to

the frame. There are a total of 4-contact points, hence this is a "4

point" cage. The photo on the left is the weld point behind the driver's seat while the right photo shows the other behind the rear seat. Notice just how much customization that went into this project. It is costly, but worth it. With this cage and aftermarket front and rear strut tower bars the vehicle handles surprisingly well for (at the moment) sitting on OEM factory springs and struts.

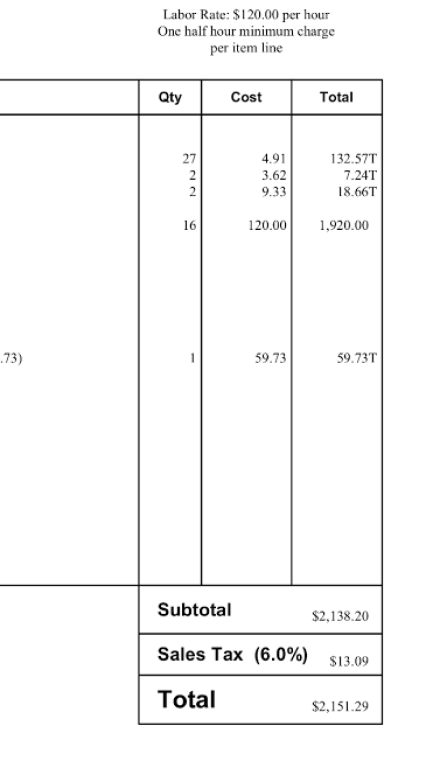

Pricing:

One reason many people never get a cage for their vehicles, even track only vehicles (except where required) is the cost. Below is the actual receipt from Mitch Piper for the tubing, materials, and labor for just the REAR 4-point cage for my car. Typically, a full 6-point cage for front and back is TWICE this cost:

Total of $2,151.39 with tax which in some cases is more than the car is worth, especially when dealing with older vehicles.

1998 200SX SE-R

For the engine, braking, & suspension.

Modifications required: T28 turbo, exhaust manifold & down pipe, ECU tune, oil lines, outlet pipes, blow off valve, boost controller, front mount intercooler, couplers/clamps etc. The SR20DE has proven itself to be very capable in handling forced induction without internal modifications, typically up to about 350WHP. This will take some time but as I wrote above, I plan on going into uncharted territory for myself. It's a perfect candidate as all I really need is the turbo parts itself and an ECU retune. The B15 Sentra SE 5-speed transmission installed has been shown to handle up to 400WHP in it's stock form, where the original transmission typically has issues once you go higher than 200WHP. This major obstacle has already been taken care of, and it gets even better as the clutch is a Clutchmasters 6-puck unsprung disc setup (FX500). A Walbro 255LPH (liters per hour) fuel pump installed provides the extra fuel needed and there is ample space in the engine bay for all the extra turbo parts as the battery has been relocated to the trunk.

- Braking Goal: A setup that performs well and is suitable for about 80% street driving and 20% track events.

Modifications required: Braking is probably the most IMPORTANT aspect of any vehicle, let a lone a modified one. As the saying goes "speed doesn't kill: rapid deceleration does!" True! Luckily for the SE-R, improving the braking is as easy as swapping in the parts from more superior Nissans. The 98 SE-R comes with relatively small and weak brakes. A *proven* braking setup that holds up for street and occasional track use is swapping in the front brakes from the 1991-1993 NX2000. This includes the calipers, mounting brackets, rotors, and some grippy pads of your choice. The rear brakes in the '98 SE-R are even more pathetic, and a popular options is swapping in the rear setup from a 1995-1999 Nissan Maxima. That will give the relatively light '98 SE-R some SERIOUS braking power. Also, some stainless steel brake lines wouldn't hurt! We'll see.

Modifications required: Other than sticky tires, the main choice is which aftermarket coilover setup to go with. There are many choices (Tein, Koni, Ground Control, K-Sport,etc). A coilover setup is ideal due to the adjustability factor and quality. Dampening usually can be adjusted by simply turning a knob on the top of the mount, allowing you to "dial in" stiffer settings for racing conditions and then soften them for more comfortable daily driving. The height of the chassis can also be adjusted. As noted the B14 chassis suffers from minimal suspension travel therefore it's imperative the vehicle is not lowered more than 1.6" or handling can actually suffer. I have already owned a 1997 200SX SE-R with Tein 16-way adjustable coilovers and other suspension modifications and it handled FANTASTIC, especially with sticky Kuhmo tires. I already have a Manzo front strut tower bar and a F1 rear strut tower bar, and along with the rear roll cage assists in firming up and limiting chassis flex during cornering. Other types of braces such as control arm braces and fender braces are available and further tighten up the chassis (see photos below). The B14 SE-R comes equipped with front & rear sway bays however they are thin. Many options are available such as the popular Progress sway bars, Intrax (see photo below), Nismo, and Suspension techniques. I have never really messed with sway bars in my SR20 powered vehicles as I felt the stock units were adequate. If you want a well handling vehicle with a soft ride, one option is to leave the OEM struts and springs on the vehicle and install front and rear strut tower braces, front fender braces, front & rear thicker swaybars, a 4-point brace (see photo) and of course, sticky performance oriented tires. This will get the job done much better than stock, however you'll find it won't get you all the way there. So as of now we'll be shooting for Ground Control adjustable coilovers, front and rear strut tower bars (any brand will do), and Progress front and rear sway bars. If I find the handling still needs to be improved I may opt to add more of the items we discussed.

(From left to right: a B14 SE-R w/ passenger fender removed to show a "Stephan's" fender brace installed; Intrax sway bar kit; Whiteline 4-point brace)

(No one really knows why Nissan added white-faces to the speedometer & tachometer of the '98 200SX SE-R and '98-99 Sentra SE yet left the fuel & temp gauges black. Also Nissan swapped in a different front end fascia for this model year which included a solid piece grille and more modern-looking crystal headlamps)

So, why do I call it this the "last of the SE-R's"?

Although there have been other Nissan models given the "SE-R" badge after the B14 chassis was retired, there's one major difference: the lack of the SR20DE motor. The '02 + Sentra SE-R came with the QR25DE motor (see more info down below) - and the '05-06 Altima SE-R had the VQ35DE motor, a large and powerful 3.5 liter V6. While these motors have their merits (especially the VQ35 which put down an impressive 275HP from the factory) they don't compare pound for pound with the original SR20. Now some 25+ years later, the SR20 is still competitive against the high horsepower Honda, Acura & Toyota motors of TODAY. My '92 VE swapped SE-R with lots of work pretty much took out anything on the road that was naturally aspirated.

Hotshot Header:

Those of you who have been modifying SR20 motors for a long time may have done a double take when you saw the word "Hotshot" - the reason being, from 1997-2004~ish, the Hotshot company developed and sold the best header for the 91-94 Sentra SE-R/95-98 200SX SE-R. I myself even had a few of them back then. Then around 2004 some foreign companies from China and Korea ripped of Hotshot's design and created their own headers with cheaper labor and materials. They undersold Hotshot on eBay and Amazon for 1/4 of the price. Since both headers made around the same power, most people just bought the cheap ones. Hotshot, a supporter of the SR20DE enthusiast community, went out of business. It is a depressing example of outsourcing cheap labor and materials to undercut the original, especially since these companies completely stole Hotshot's design. Hotshot's header was more expensive because of better materials and that they spent nearly a year dyno testing to give us the best product possible that made the most power. Hotshot eventually did file suits against these companies but I am unsure of the result. Anyways, although my plan for the car includes forced induction, a friend was selling the now-extinct 4-2-1 header for a few dollars and I picked it up. It may not be the prettiest thing as it's probably a decade old and it has some issues and rust here and there, but these have been dyno proven to increase peak WHP by 10-14HP on an SR20DE especially when used in conjunction with other modifications. Of course, this header is NOT compatible with a turbo exhaust manifold but I decided to slap it on the other day at a friend's garage for the heck of it. Installation is not difficult; the hardest part is dealing with rusted and/or breaking bolts at the catalytic converter to install the down pipe and fitting the primary onto the engine block with various things in the way (radiator fans, wires, oil dipstick etc.) You can definitely feel a some extra power higher in the rev range.

(The Hotshot header primaries. Notice the fitting for the 02 sensor on the bottom right. It may not be pretty but it gets the job done)

Semi-cold air intake:

Having an small section of extra 45 degree 3" intake piping laying around, I decided to add it to my current warm intake setup. In my opinion this makes it a "semi" cold air intake. It does certainly add some power and a cool sound, but doesn't sit in lower driver-side fender well so there isn't the dreaded potential hydro-lock issues. It may be the best of both worlds (although a TRUE cold air intake has been shown to make as much as 4-5 more peak HP on the dynos) - couple photos:

Notice the air filter is situated further from the engine bay, AND the extra piping length adds a bit of resonance. The sound is clearly noticeably and my "butt dyno" says about 2-3 peak HP.

The 1995-1997 200SX bumper conversion:

The '98 SE-R bumper is known as the "fish mouth" look because of the resemblance to, well, a fish. Some '98-99 SE-R owners actually go out of their way to swap in the '95-97 bumper because they like it better. Since styling is always subjective, see what you think:

MANZO front strut tower brace:

I picked up this up on cheap on eBay. A strut tower brace is beneficial by inhibiting chassis flex during cornering. It also shines and looks nice in the engine bay :) Installation is simple but here is a brief description. You need to:

1) Loosen and remove the 6 strut tower nuts (3 on each side which are usually 13 or 14mm)

2) Place the mounting ends of the brace on the bolts on each side. Tighten the nuts back down in an even pattern.

3) Most strut braces can be lengthened or shortened by turning the large in-line nuts on either side for a proper fit. You can also tilt the bar forward so it does not make contact with the any of the emissions equipment up top (especially in '98-'99 SR20DE motors, prior '91-97 motors did not have this issue).

4) Once you have the bar positioned as desired, tighten up everything and go for a ride! You will feel more firmness especially on faster turns. The strut tower brace is a great and cheap modification, and paired with a rear strut brace will make the B14 SE-R handle MUCH better. The braces typically cost around $30 each on eBay, so it's a very inexpensive but fantastic modification!

The chrome plated strut brace really shines in the sun:

F1 Motorsports rear strut tower brace:

F1 Motorsports rear strut tower brace:

(The rear bar comes in three pieces; you must attach both end links to the strut towers while placing the bar in place to get a proper fit)

In addition to the front bar most usually get a rear brace, however they are a bit harder to come by (especially for the B13 SE-R chassis). The bar bolts onto the strut towers as it does in the front. You need to remove the two bolts on each side, put it on and tighten it down. On the B14 SE-R you can simply cut two small holes in the trunk carpeting so the bar passes through for a cleaner look (although I haven't yet). Here is the new rear brace installed:

Driving impressions: having both front and rear strut tower braces along with roll cage allows the car to rotate quite well around corners, even with the OEM struts and springs. More suspension mods to come!

Replacing the Clutch Cable:

It finally happened: at 196,000 miles my clutch cable SNAPPED in my '98 SE-R while I was pulling into a convenience store. The clutch cable in all 1991-1998 SR20DE motors with manual transmissions (obviously) is NOTORIOUSLY known to break. It's one of the weak spots in these vehicles (Nissan would later rectify the situation by switching to a more reliable, hydraulic setup in the 2000-2001 Sentra SE).

This was actually the THIRD clutch cable to break on me! It happened once in my '98 Sentra SE, again in my '92 Sentra SE-R, and now the '98 SE-R, all three while I was driving somewhere, leaving me STRANDED.

Luckily, knowing how lousy these clutch cables are and also getting a feeling the current cable was on it's last legs, I had been carrying a spare clutch cable in the trunk. Since I also carry my tools with me I was able to replace the cable with the assistance of a friend in the parking lot. I am VERY thankful to the Lord above the cable did not snap at a stop light in heavy traffic!

So what's the problem?

Over time (and as the miles rack up) the area where the cable bends at an angle and thus attaches to the pedal begins to wear and eventually just snaps (in above photo the pedal side is at the bottom). Rarely does the cable break in the engine bay or at the clutch arm on the transmission shaft.

WARNING SIGNS: your cable may be in the danger zone when it begins to "creak" or "groan" whenever the clutch is depressed, and/or it takes greater physical effort to depress the pedal. If you are experiencing either of these issues, or if you have the original cable still w/ high miles (as some have been known to break without warning) **YOU MAY BE IN THE DANGER ZONE** - Once the cable snaps the pedal sticks to the floor, you cannot shift, and you will be left STRANDED, so your best bet is to be prepared and keep a spare cable in the trunk! RockAuto.com sells new cables ranging from $8 to $36 depending on the brand & quality. IT IS WELL WORTH IT TO GET A SPARE, at the very least, for the peace of mind.

(My actual clutch cable that snapped; notice it's on the pedal side)

Installing a new clutch cable:

First you need to remove the broken cable and pull it out, and do the same inside the car down at the clutch pedal. You will need open ended 10mm & 12mm wrenches and probably a socket set. On the transmission side, loosen the 10mm nut holding it and then loosen & spin the adjustment "wheel" to remove it from the clutch arm, as shown below, it will come apart allowing you to pull it out from back by the firewall (there may be two 10 or 12mm bolts holding the mid-section of the cable near the driver's side of the firewall, depending on your model).

(Above left: the cable still attached, above right: the cable removed)

The harder part is threading the new cable through the firewall & attaching the pedal end of the cable inside the cabin, mostly because it's a tight space and dark. You'll probably need to slide the driver's seat fully towards the rear and use a flashlight. Lay down under the dash to find the point on the pedal where the small, rectangular end of the new cable attaches. While it's not rocket science, it can be a real pain if you can't see what you're doing:

The photo above is a cross sectional of the clutch pedal assembly & cable removed from the car. You can see where the new cable attaches to the pedal.

FALL 2015 - 200SX SE-R parts car

In the fall of 2015 I picked up another SR20 powered vehicle from a friend, not in the best physical shape but mechanically it was sound. It was a teal colored 1997 200SX SE-R, lightly modified and ran good except the clear-coat on the original paint was peeling and it was rusting badly. I pulled many good parts off of it including the complete A/C system, full exhaust, bigger camshafts (see below), a B&M short shifter, and more. Unfortunately, the rust was really bad.

I realized the car was just taking up space and I had no intentions of trying to get it road worthy due to the rust, so in the summer of 2016, after removing many of those goodies to install in my 98 SE-R, I let her go. Here are pics of her being towed away by her new owner (an avid SE-R road course racer who is going to use for parts). The rust was just too much to overcome unfortunately, even though the motor and transmission ran strong. Almost 210,000 miles all original!

I only drove it only ONCE: the drive home immediately after I purchased it. Poor little car. RIP.

I only drove it only ONCE: the drive home immediately after I purchased it. Poor little car. RIP.

Jim Wolf Technology S3 camshafts:A long time ago, circa 1997-2001, there was 1 single modification for the SR20DE motor that was consistently making an extra 14WHP on the dyno. Those were the JWT "S3" camshafts. Here's a short article about them from the June 2000 issue of Sport Compact Car:

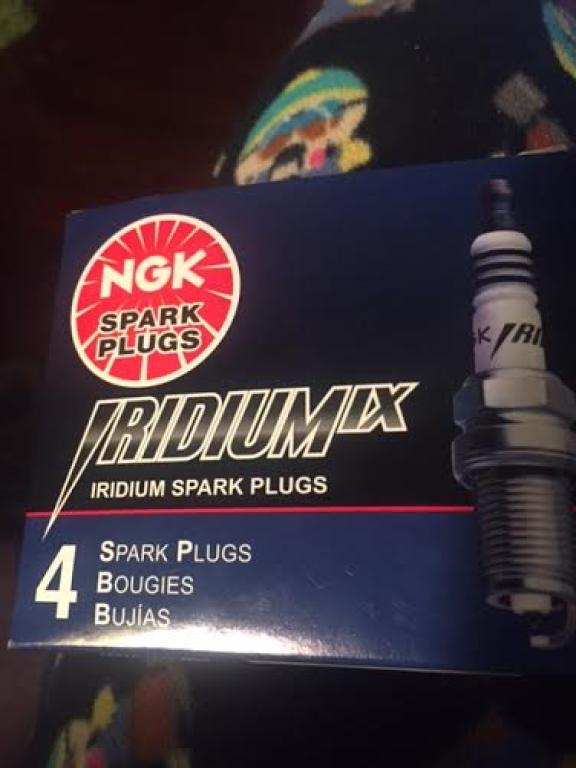

The chart above shows how the JWT S3 cams are a great modification for the SR20DE motor, N/A or turbo, and this is just the horsepower and torque gains over the much more aggressive 1991 cams that came in the original SR20DE motor. The gains on a 1994 and newer SR20DE motor are nearly double this! Below we will describe the removal of the OEM cams and installation of the JWT S3 cams in full detail in my 1998 SE-R. I also first purchased these NGK Iridium spark plugs to swap in during the cam installation:

NGK Iridium BKR6EIX-11 are probably the best spark plugs for the SR20DE engine. Now onto the actual cams....

THE JORDAN WHITE SR20DE CAM SWAP PROCEDURE:

Some of this information may be redundant for those of you who are quite experienced with these motors, and truth be told, this was actually my 6th cam swap in a SR20, but I decided to photograph and document it anyway. There are some write ups on the internet on how to do this, but I found they skip steps or don't mention very important things etc. So this write up is aimed towards those who are new to the SR20DE motor and/or who are learning how to work on and upgrade their own cars. My way is my way and you may have a better way, but of course I must post this DISCLAIMER that I'm not responsible if you try any of these methods and something goes wrong. It is very easy to ruin an SR20 motor if you're not careful during a cam swap. Here's some things I've seen during cam swaps that have ruined or nearly ruined SR20 motors:

1) The motor not being at TDC (top dead center) before beginning

2) Skipping a tooth on the timing chain down at the crank; screwing up the cam timing

3) Dropping a bolt, washer, socket, etc. down into the motor

4) Trying to use a "wedge" to block the timing chain tensioner instead of removing it (more on that later)

5) Not removing or replacing the cam bearing caps in the proper way

6) Generally goofing off and not paying attention, not checking and re-checking your work

That being said, while not being especially "difficult" - a cam swap in the SR20 motor is not to be taken lightly. It's a time consuming and involved process. You are basically doing heart surgery on your motor and must exercise caution and pay full attention. Eliminate distractions the best you can and if possible, have a friend at least somewhat familiar with working on cars help you out. DON'T RUSH. Allow yourself at least twice the amount of time to complete the job. If you're working outside and it starts to get dark, STOP. Don't try to beat the sunlight. Avoid drinking too many beers as it will dull your senses (I know for some of us that's part of the fun) - but trust me, you don't want to mess anything up. While many things can go wrong, if you do it right, the results are quite rewarding :)

"SPORTCAM" imprinted on the JWT S3 intake cam

TOOLS & THINGS YOU WILL NEED: A jack, jack stands, wheel chocks, socket wrenches, extensions of various lengths, small swivel, pliers, 10mm, 12mm, 14mm, 16mm, 24mm, 27mm sockets. Breaker bar, torque wrench (although you can get by without one). A large 1" open ended wrench, 24mm open ended wrench, long& thin10mm open ended wrench. Flat head screwdriver, standard spark plug removal socket, at least 1 quart of fresh oil, oil filter wrench, zip ties, clean towels, RTV gasket maker sealant, a long magnet extension (just in case). Thin plastic disposable gloves, timing light gun, magnetic tray, a black or blue Sharpie marker. There are also several optional things you can do:

OPTION #1: New valve cover gasket set from Nissan parts department. It can't hurt to get it (about $34 from the parts department) however I've always been able to re-use my old gaskets; it really depends on the condition of your old one, and you won't find out until your remove the valve cover. Order at least a week in advance.

OPTION #2: Upgraded/improved timing chain tensioner & gasket. The timing chain tensioner is a simple and small device with a lock and pin mechanism that enters the block near the oil filter and places the necessary tension on the timing chain, and thus the camshafts, which ultimately drives the motor. Sometime around 1997-1998 Nissan introduced an improved design you can purchase but will cost you anywhere from $60-$100. Again, this is optional. Assuming your old tensioner was in working order, it will come out and go back in fine, and continue to function properly. However if want the better tensioner and don't mind spending the extra cash you may as well get it since you will be removing it anyway. HERE is a (ridiculously) detailed description of the process, and you can get the new improved tensioner w/ new gasket HERE from Greg at G-Spec.com.

OPTION #3: 4 fresh quarts of your favorite (preferably synthetic) oil and a filter. It's always a good idea to do an oil change when doing a cam swap. You will leak oil when removing the oil filter and timing chain tensioner anyway, but it's up to you.

OPTION #4: A set of new spark plugs. In my method you will need to remove the spark plug from the #1 cylinder anyway. With the valve cover off it's much easier to access the plugs. Since they're right there, why not? You can get a set of 4 NGK copper BKR6E's for less than $14 a set at AutoZone. Since my spark plugs have probably not been changed in many years, I got the more expensive, NGK iridium plugs, BKR6EIX-11's. They are about twice the price but "last" twice as long.

HERE'S HOW TO DO IT STEP BY STEP:

(A dirty SR20DE motor in my 1997 SE-R, about to be opened up)

2) Use pliers to open the clamps on the various hoses and

pull them away from the valve cover. There's clamps in the

hose leading to the intake, another to the canister up front and at the

PCV valve on the top left. Remove the spark plug wires from the cylinders

leave them connected to the distributor. Pull the throttle cable back

towards the firewall and get it out of the way.

3) (Note: the following step applies to the "lowport" 1994+ SR20DE motor. The 1991-1993 motor has different valve cover bolts with acorn nuts instead). Get your wrench and a 10mm socket with an extension of comfortable length for you and start breaking the valve cover bolts loose. They should break fairly easily. Break them loose one by one, going around the cover at random from side to side. Be careful not to drop any (if you lose one you can't just go to Sears Hardware and get a new one). There is washer/grommet that needs to be removed after the bolt slides out, usually with needle nose pliers. Sometimes they come up easily, sometimes you need the pliers. Get a big magnetic tray to put these all in. ALL of the valve cover bolts are identical EXCEPT the center bolt in the middle of the cover between the #2 and #3 cylinders. That bolt is longer and different so make note of it. Take your time and be patient. You will need to remove some of them by hand after they're loosened. Once you get them all you should have something like this in your tray:

4) Now before removing the cover, double check that you've removed all of the bolts and their respective washer/grommets. Some of the bolts are difficult to see and/or access because of things in the way, so either use a swivel or temporarily remove the obstructions.

5) The valve cover should pull off fairly easily and reveal the internals of the motor. Mind the gaskets and make sure you keep them in a safe place if you are not replacing them with new ones. Place the valve cover, the little hoses and the gaskets in a safe place. FROM NOW ON YOU NEED TO BE EXTRA CAREFUL handling your tools and bolt over the engine bay. The effects of a random socket falling down into the motor could be devastating. My motor above had 209,000 miles at the time the photo was taken but was well taken care of (I.E. - regular oil changes). Depending on how well your SR20DE was maintained, it may look better or worse. I was quite pleased with mine.

6) Place the white towel (lint free) over the exposed engine for now to prevent foreign objects from falling into it (you never know!) Get your breaker bar out to loosen the four lug nuts on the front passenger side wheel, then ack up the car on that side and completely remove the wheel.

BE CAREFUL.

Your car is sharp and heavy. You are soft and squishy. Use quality jack stands and wheel chocks, and NEVER get under a vehicle supported by only a scissor jack.

7) Once you've removed the wheel you will see the plastic splash shield. Hopefully yours isn't as filthy as mine was :) The shield needs to be temporarily removed to access the crank pulley. There are three 10mm bolts you need to remove to bend and pull it out of the way.

Now you will see this:

8) You are looking at the crank pulley oil pan (just below the belts). The center bolt on the crank pulley is what we're after here. We need to manually rotate the motor with our breaker bar and 27mm socket (CLOCKWISE) to get the motor to TDC (top dead center).

THIS STEP IS ABSOLUTELY CRUCIAL AND PERHAPS THE MOST IMPORTANT OF ALL. If you don't set the motor to TDC and attempt to remove the cams you will damage the valves and possibly worse. There is no room for error so pay close attention:

9) Place the breaker bar and 27mm socket on the crank pulley bolt (as I did above) and leave it there a moment. Remember to have to the transmission in neutral. It's not that difficult to rotate the crank but if your bar is extra long you will have to repeatedly readjust your position because you'll run out of room and hit the fenders/strut.

Before we move onto the next step, let's talk a little bit about top dead center (which ill be referred to as TDC from here on out) as it relates to the SR20DE motor. What is TDC?

If you want to know more,

THIS THREAD from the SR20-Forum is worth a quick read on TDC and camshaft timing. The official definition of TDC is the

point where a piston is just about to change from an upward to a downward stroke.

10) It's crucial you get the motor to TDC. To do so and to be

100 percent sure, do the following

: remove the spark plug from cylinder #1 using your spark plug removal socket, and place a long, thin screwdriver, or long magnet thingy (like I did) in the cylinder. Use something that is long enough that you can still grab it, obviously. See photo:

Here the spark plug in the #1 cylinder has been removed and a long "magnet thingy" has been inserted in. Why do we do this? Will get to that in a second, but first let me show you how TDC looks on the crank pulley:

THIS IS PROBABLY THE MOST IMPORTANT PART OF THE PROCEDURE:

TDC on the SR20DE is indicated by the pointer being on the SECOND MARK from the LEFT on the crank pulley as well as two other factors: the cam lobes closest to the timing chain (on your left if you're standing in front of the car looking down at the motor) are pointing AWAY f

rom the center of the motor and the cam sprocket dowel pins on the intake & exhaust cams being at 10 and 12 o'clock, respectively. That means on the intake cam (the cam closer to the firewall) the dowel pin should be at 10 o'clock and the dowel pin should be at 12 o'clock.

So why did we place something long in cylinder #1? This is because as you rotate the crank the screwdriver/magnet thingy/whatever will be pushed up and fall down as it opens and closes. TDC can be achieved when the screwdriver is at it's highest point. For TDC in the SR20DE, you must make sure these four things all occur at the

same time:- The pointer on the crank pulley is pointing to the 2nd mark the from the left

- The camshaft lobes closest to the timing chain are pointing away from the center of the motor

- The screwdriver or whatever you used to put in the #1 spark plug cylinder is at it's highest point

- The intake cam dowel pin shows 10 o'clock; the exhaust cam dowel pin shows 12 o'clockALL of these must be present or you are not at TDC. Don't fret though. Rotate the crank pulley clockwise at least another full cycle until all of these are achieved, then we're ready for the next steps.

SIDE NOTE: Some SR20DE's have this yellow mark on the timing chain. This is a picture of a different motor than the rest of the photographs, from my 98 SE-R. Notice the yellow mark on the intake side. This photo was taken at true TDC:

This mark is NOT present on all SR20DE's. So don't worry if you don't see it.

11) Zip tie the timing chain to the sprockets in at least 4 places, I recommend at least 2 on each side. This ensures the cam timing will not get thrown off:

12) Remove the timing chain tensioner. Notice I said "remove" - not block. There are many instructions out there regarding the timing chain tensioner where you put a "wedge" in place to "block" it from putting tension on the chain.

I HIGHLY RECOMMEND REMOVING THE TIMING CHAIN TENSIONER AND NOT JUST "BLOCKING" IT.

I've seen many problems come from the "block" method, too long to get into here, so just trust me on this one.

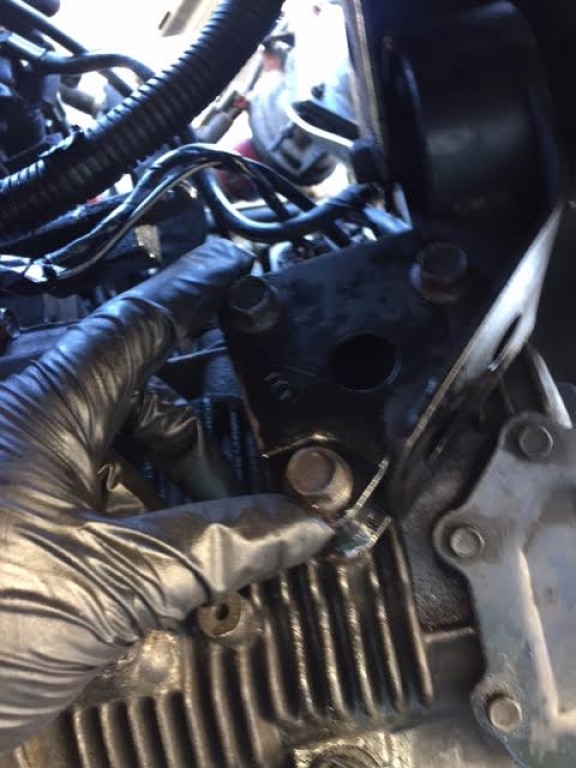

To remove the timing chain tensioner:

a) First remove the oil filter, and put a little paper towel or rag under it as it will leak oil a bit. Luckily the SR20 oil filter is in a location where it can be removed when oil is still in the pan. You will now see this:

b) See those two extending bolts? That's the timing chain tensioner still installed. Get your wrench and attach a 10mm socket to the nuts (they had already been removed in this photo) and do your best to remove them. You may need to use extensions, a swivel, or even a long open ended 10mm wrench. I'll be honest, they're not the easiest couple of bolts to access. There are also 2 little washers under each bolt so make sure you get them out too. Keep your little rag stuffed in and around the oil filter shaft so nothing falls in there.

(NOTE: depending on how well your tensioner is stuck in the block, it may either pop right out when the second nut is removed, OR it may take some "convincing." Be ready and aware of the second nut flying off once it's loosened as the tensioner may pop out with some force. If your SR20 has a lot of miles like mine did, it probably will stay stuck there even when the bolts have been removed. To free it, get a long flat head screwdriver and place the edge between the tensioner and the block and gently tap the end of the screwdriver with a rubber mallet or similar tool. It will eventually pop free. This is the timing chain tensioner removed:

Don't lose it the little gasket!

This is the tensioner in it's unlocked position. You will eventually need to compress it and get the hook to attach to the pin before you reinstall it, but for now just set it aside in a safe location, preferably in a plastic cup filled with fresh motor oil.

13) Now the timing chain should have a little more slack in it, so let's start removing what's holding the camshafts in place! First, remove the timing chain guide. It is held on by two 12mm nuts. Use your wrench and an extension. REMEMBER to be careful and extra vigilant not to drop any tools or bolts down into the motor. Photos:

The timing chain guide still attached on the far left.

Loosening the 12mm bolts

The bolts/washers removed and the guide free, and what it looks like when it's gone.

Take note of the first lobes on both intake and exhaust cams facing away from the center of the motor, which is 1 of the indications you are at TDC :)

Set the timing chain guide and the hardware in safe place free from any dirt or debris it could pick up since it will be oily.

**CONTROVERSY: There is debate among the SR20 community about the timing chain guide being necessary at all. Nissan put the guide in all SR20DE motors from 1991-1997, however in 1998 they completely removed it. The belief is that the guide causes "start up clatter" which sounds like a bunch of nails in a glass jar shaken up for a second or two (especially when the motor is started up on cold mornings). There is also evidence that the guide physically damages the timing chain over time. Whether or not you want to reinstall the guide is completely your choice. Personally, if the motor came with it, I'd put it back in, but you can do your own research on this topic, just Google "SR20DE timing chain guide." Whether or not you put it back or not, just remember that Nissan got rid of it voluntarily in 1998.**

14) Next we want to physically break the camshafts loose from the cam sprockets. You want to break them LOOSE but not actually remove the bolts yet. Depending on your particular motor, this could take a lot of strength. Several years ago on a different SE-R mine were on so tight that to break them free it took a friend standing on his hands, using his legs to push on the breaker bar while I held each cam in place with the wrench! If you're one of those super strong guys I wouldn't worry much, but if not you may want to ask a friend or significant other to help out for a moment.

Attach the 24mm socket to your breaker bar and place it on a main cam bolt. Take your 1" open ended wrench and place it on the first cam hex (it's the little slot before the first lobe) see the photo below:

In this photo I actually used a second 1" open ended wrench on the main cam bolt, you can use whichever you wish. You use your right hand to hold the cam in place, and your left to break the bolt loose (make sure you are turning it in the correct direction to loosen!) You must hold the cam in place with the 1" open ended wrench or you will likely rotate the cam, plus you DON'T want to use the motor or timing chain for resistance. Once you break the bolts loose you can stop for now.

Now we can remove the distributor. Again, this is my method that I have found works the best. Some would have chosen to remove the distributor earlier, I like to before I begin to remove the cams. The distributor is held on by two 14mm bolts on it's top and bottom "ears." Removing the distributor also leads you to remove your first cam bearing cap. This one is different as it is held down by two 12mm bolts:

Since the distributor only effects the exhaust cam I'd advise you start with that cam first.

DO 1 CAM AT A TIME. You don't want to mix up which cam bearing caps go where, and you can concentrate on each one a little better.

16) Start breaking loose the cam bearing caps using your wrench, extension and 10mm socket. Break them loose but don't remove. The bolts should take a moderate amount of force with a average wrench. I recommend using an extension as it's easier and gives you a bit of leverage too. Break each bolt free in an "X" like pattern, almost randomly but from separate sides of the cam. Example: loosen one in the middle, then one all the way on the left, then on your right, etc. and keep doing this.

You want to loosen the cam slowly from all over and NOT from one end to the other:

Removing or replacing the cam bearing caps is probably the most time consuming part of the whole process. The bolts are much longer then they appear but are not all the same length. Once all the bolts have been broken loose, continue to move around the cam and loosen them more and more until they come free. Remember to loosen each one a few turns at a time when they're still on tight. Keep everything in order and remember exactly which cap goes where, and where the oil squirters were located.

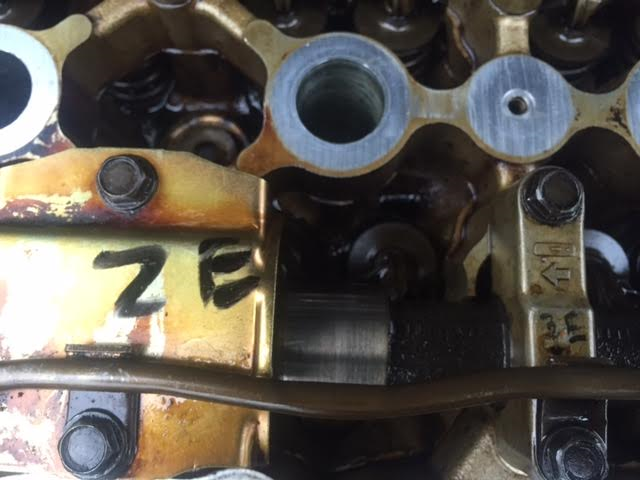

I recommend:

a) Before you remove each cap, get your sharpie and mark it's location. For example, for the cap closest to the timing chain on the exhaust cam, you would write "1E" - meaning 1 for the first cap and "E" for exhaust. For the 4th intake

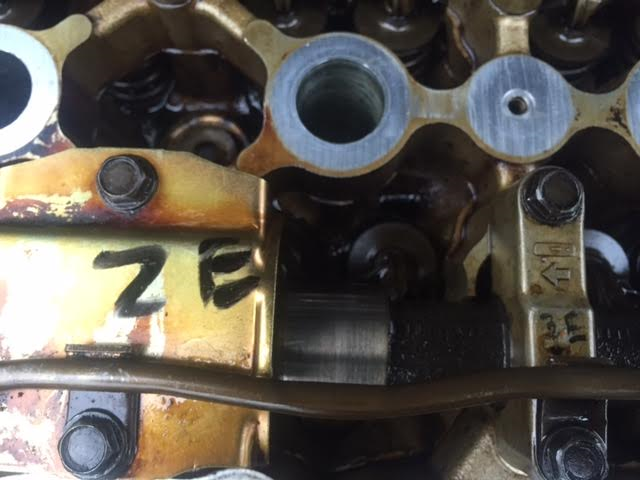

cam cap write "4I" for fourth cap from the left, and "I" for the intake cam. You get the picture. It would look something like this:

On the oil baffle on the left (which covers the 2nd exhaust cam bearing cap) I wrote "2E" and you can also see I wrote "3E" on the cap to it's right. A very simple thing to do, but a very good idea.

b) Lay out the cam bearing caps in their proper order (and eventually the cams) on a clean towel or piece of cardboard somewhere safe, like this:

Clearly this photo was taken at the end of my cam removal process. I laid everything out as if I was looking down at the motor from my angle, identical to what I was actually doing. The exhaust cam is on the bottom with it's caps, baffle, and oil squirter in the correct order, and the intake cam on the top laid out the same. I suggest having a designated spot to spread this all out away from your work area, and try to keep the appropriate, matching bolts still inside the caps to minimize confusion (as I also did in the photo).

17) Now let's fully remove the cam sprocket bolts. Do 1 at a time, and after you've gotten them loose enough, turn them by hand like this:

Once the cam bolts are out the sprockets will come right off the cam dowel pins but remain attached to the timing chain because of your zip ties. Get another zip tie or something similar to hold the chain up as you want to keep it from falling down into the motor. Dropping it or

letting it fall can occasionally

cause the timing chain to

come off down at the crankshaft in which case your cam timing

would be off and a pain to correct. This is known as "skipping a

tooth on the crank" and it not something you want to deal with, so be careful:

In this photo I actually used an old spark plug wire and a paper towel (it was what I had handy) to hold the chain and sprockets up. Use whatever as long as it works.

18) Now remove the cams from the motor. Sometimes one of the cams will already be loose and come right out, sometimes one will seem "stuck." Don't worry, this is normal. If one seems stuck GENTLY tap on the ends of the cam with a wrench (something dull that won't cause scratches). The cam will pop out. Once the cams are removed there's nothing holding the rocker arms down so pay close attention that none have been disturbed from their perches. If it does happen it's no big deal, simply re-position it by hand like the others are. Your motor will now look like this:

If you purchased new spark plugs now would be a good time to install them. If not, just re-install the one you removed from cylinder #1.

19) Get out your quart of fresh oil and pour a generous amount down onto the rocker arms and everywhere the new cams will be sitting, just avoid the spark plug wells. You can stuff small paper towels down in there to soak any oil that gets near it.

20) Now it's time to basically do everything we just did to remove the cams,

just kind of backwards. Again, I suggest doing 1 cam at a time. Oil up each of your new JWT cams and position them. The easiest way to tell which cam goes where is that the exhaust cam has the slot for the distributor on the end. Place the cam with the first lobe pointing away from the center of the motor and with the dowel pin inside the cam sprocket slot. It should slide in easily. Here is a photo of the JWT intake cam positioned in place:

IMPORTANT:

IMPORTANT: It's common for the cam on the driver's side of the motor to be "sticking up" once put in place. Be careful if this happens. I actually broke 2 cam-bearing cap bolts on the driver's side of the engine and had to find replacements. The best way to avoid this, if it happens, is to tighten down the cam bearing caps in what I call a "wave." Start by

slightly tightening the bolts on the left side (passenger side of car) and move your way down towards the driver's side of the cam. Tighten in an X pattern. Keep doing this as it will put less pressure on the bolts (which are surprisingly weak) and pull the cam close to it's seated position. Once the cam is seated firmly on both the passenger side, middle, and driver's side, you may start using your torque wrench to tighten them all (again in an X pattern) to the proper specifications.

21) Make sure no rocker arms (and thus, shims) were disturbed from their position and begin to replace the cam bearing caps, one at a time. Hopefully you marked and placed them in proper order after they were removed so it should be fairly easy. TIP: the arrows on each cap always point towards the LEFT or timing chain side of the motor. Tighten each bolt gently by hand until all are in their proper positions then slowly tighten them with your wrench in the same "X" pattern and go from each side of the cam to the other. Left, right, middle. Right, middle, left. You get the picture. Never tighten it down fully in one place before the others are. If you have a torque wrench, once all the bolts are quite tight, tighten them down to about 7.0 ft-lbs each. For the exhaust cam, the two 12mm bolts at the distributor should be tightened to about 16 ft-lbs. MAKE SURE THE ROTOR ON THE DISTRIBUTOR FITS IN WITH THE CAM SLOT!! You may need a second person to position and push the distributor into the proper location while you tighten the bolts. If you don't have a torque wrench, tighten all the bolts to the same amount to the best of your ability. Recall how much effort it took to originally loosen them and try to get them to that point. It may take some trial and error of tightening one and loosening it to get the "feel." My point is: it's always best to have a torque wrench!

IMPORTANT NOTE: If you have already advanced your ignition timing by moving the distributor, disregard the "JWT SR20 camshaft install" instructions which are found at: http://jimwolftechnology.com/wolfpdf/caminstallinstforsr20.pdf - if you look at that page, you'll see that JWT says that your distributor is only in the proper position if it's in the center. This is not true if you have previously advanced your ignition timing (like many SR20 enthusiasts do to gain a few free HP). To make it simple: the distributor should be replaced in the same position it was before you started the cam install.

UPDATE: So according to Jim Wolf Technology (who developed these SR20 camshafts) - the S3 cams make the most power when ignition timing is set at 15 degrees, while mine was about 20 degrees here. Taking their word for it, I decided to retard the timing to about 15 degrees, and I *think* I picked up a little more high end power. So remember, put the distributor back in the same timing position it was before you removed it, then if you so choose, reset the timing at a later time once everything is all back together and your car is running properly with the new cams.

22) Tighten the sprocket bolts in by hand. Make sure each sprocket is mated correctly to the cam with the dowel pins and then start to make the bolts tighter. Use your 1" open ended wrench again on the first cam hex to hold each cam in place, and another 1" open ended wrench on the sprocket bolt to slowly tighten it. Once the cam is seated well get out the breaker bar and 24mm socket and tighten them with that. If you have a torque wrench that goes up high enough, tighten each of them to 110 ft-lbs. Again if you don't have one, just tighten them really really well (again recall how much effort it took to loosen them originally).

23) Carefully remove any zip ties you placed on the sprockets and chain, and replace the timing chain tensioner. This can be a tedious procedure if your hands are big, or if you don't have enough light. My suggestion: get plenty of light shining down there and be patient. First, you must compress it and attach the little arm to the pin. This can be done by placing it on a hard surface (the ground) and pushing down with one hand, then using your other hand to get the arm to latch to the pin. You need to manually press in the actuator with either your finger or a flat head screwdriver to allow it to compress. When replacing it, make sure it is oriented correctly with the gasket and be very careful not to drop the little washers anywhere. Keep your paper towel or rag jammed in oil filter hole. Take your time and use your swivels and/or temporarily remove hoses that get in the way if needed. The tensioner should now be snug.

24) Replace the oil filter. Coat it with a layer of oil and tighten about as much as you can by hand (as usual).

25) Get your breaker bar and the 27mm socket and rotate the crank clockwise about 1/4 of a turn to fully engage the timing chain tensioner. If you have a friend helping you out, this would be a good time to watch that both the intake & exhaust cams rotate smoothly. ONCE AGAIN, double check your work. Make sure no rocker arms were disturbed, all arrows on the cam bearing caps point towards the PASSENGER side of the car, and all bolts are snug.

26) Get your RTV grey sealant out and dab some in the area of the "half moons" of the valve cover gasket. Make sure the spark plug gasket is still lodged up in the valve cover (it often is when you remove the cover - if not, put it back in). Carefully place the valve cover back on the block, making sure the gasket remains in place. Now replace bolts and washers. There is 1 long valve cover bolt that goes in the center between the 2nd and 3rd spark plug wells (FYI). Tighten them from left to right and middle, slowly and evenly. Never tighten one all the way. Keep tightening randomly all over the valve cover until it is properly seated. If you have a torque wrench, all the valve cover bolts should be torqued down to about 7.0 ft-lbs. Don't over tighten them as they WILL break.

27) Replace all hoses that lead to the valve cover you had removed, use pliers on the clamps. Replace the spark plug wires in the proper order.

28) Double check everything (no loose tools in the engine bay, all wires and hoses are connected, etc.) Reconnect the battery!

29) Start up the motor. DON'T WORRY! If you did everything correct it may still run a little funny but will smooth out. The motor will "lope" at little, this is normal with a bigger cam for the SR20. If the cams are brand new you should keep the motor under 4000RPM for 20-30 miles of driving to make sure they are properly "broken in" and keep it under WOT for a couple days or regular driving.

30) You're done! Now go get em!! If you have any questions e-mail me at Jordan@jordanwhitemusic.com

Here is a comparison photo of the JWT S3 cams with some pretty nasty looking OEM cams from a 1997 200SX SE-R with over 200,000 miles on it. As you can tell the OEM need a good cleaning. The JWT S3 cams have probably 10,000 miles on them and thus look quite good. Very minimal cleaning will be needed and no scorches or burrs were detected.

Swapping to an "eBay brand" header

Getting it cheap, I decided to install one of the 4-2-1 "eBay" exhaust headers on my car. Depending on the brand they go for anywhere from $100-$200 shipped, brand new! Back in the day the Hotshot header went for as much as $400. Then companies stole their design and offered a product nearly as good for 1/3 of the price. Since Hotshot has been out of business for many years, I decided to give the "eBay" header a shot. Here is a side by side comparison of both headers, and as you will see, the biggest difference is the diameter of the secondary piping:

The original $400 Hotshot header on the left, the $120 eBay header on the right.

Rear view. At first glance, they appear similar, but:

The Hotshot header secondary diameter. Note how the coating has long since burned away.

The "eBay" header secondary. Relative to the Hotshot it's much bigger which helps to increase exhaust scavenging, so it appears for vehicles with more modifications the eBay header is the way to go. I did notice a little extra pull up in the higher RPM range.

Installation is straight forward. You should always use a new gasket too.

On the EGR issue

On the EGR issue: If you install an aftermarket exhaust header on the SR20DE, there is the issue of what to do with the EGR system (exhaust gas re-circulation) which is a tube that connects to the top right of the header primary. It was put in by Nissan solely for emissions reasons; while it doesn't do much in general it will throw a check engine light if it's not properly connected or removed. Most aftermarket SR20DE headers have a bung opening for the original EGR tubing that can also be blocked off with a small plug taper (available from Nissan for about $10). The issue is, the EGR pipe is quite difficult to remove if it's rusted. Many SE-R enthusiasts completely remove the EGR system and install a block off plate and put a resistor in the wiring harness to fool the ECU. Above left is a photo of the EGR pipe before being screwed into the eBay header bung, while the second photo I'm using a 24mm open ended wrench to get it in.

Left:

Left: eBay header installed.

Right: holding a plug taper used to block off the EGR piping if you have removed it.

Update: In June 2016 while installing a Stromung exhaust (more on that just below) - we noticed that the flex area of the downpipe was beginning to fail and leaking. I ordered a brand new eBay header

(side note: it's amazing you can get these now for as low as $100 shipped!) and installed the new flex pipe, which really cut down on the exhaust noise. Here are some photos of them side by side. Luckily they are identical and the new flex pipe matched right up with the primary that was already on the block:

Notice the pretty chrome finish on the new piece? Once the old one looked like that as well. That's what happens :(

The failing flex area of the old downpipe (left) and the brand new one for comparison (right). I'd rather have a downpipe with no flex area at all, but those are typically reserved for the expensive 4-1 header designs and increase vibration in the chassis.

From below the car, the new flex pipe installed (left) and it's flawless connection to the older primary (right). Hopefully this flex section lasts a long time.

From below the car, the new flex pipe installed (left) and it's flawless connection to the older primary (right). Hopefully this flex section lasts a long time.

The Stromung 2.5" cat-back exhaust:

July 2016: Despite the bolt-on modifications on my '98 SE-R, I was still was using the OEM Nissan exhaust. This is a problem as the OEM tubing at some spots closes down to less than 1 1/2" in diameter. While exhaust systems don't do much to increase power on otherwise unmodified SE-R's, once you get into items like cams, the OEM exhaust system can really hold the motor back. A good quote I once read about modifying engines is "you can only eat as much as you can shit." Anyways, the Stromung system is a high quality aftermarket exhaust that includes 2.5" in diameter mandrel bent tubing with a resonator ending with a high quality, stainless steel straight-thru design muffler. It appears from

their website that they no longer produce this for the B14 SE-R, however when brand new this system went for $500-$600. Quite pricey! This one was about 8 years old and being a high quality piece has held up well.

Left: the Stromung exhaust on the garage floor attached to the catalytic converter, waiting to be bolted under the car.

Right: the OEM exhaust tubing and resonator removed. Note the minute diameter of the piping, which surely holds back some power on modified SE-Rs. I also installed brand new gaskets at the front and rear of the catalytic converter since the old ones were falling apart anyway. You should always replace the gaskets and you can get new ones direct from Nissan or Autozone for around $8-$10 bucks but they may have to order them.

Left: the Stromung muffler wisely utilizes the OEM exhaust hanger locations, making it possible to install in your driveway without needing a welder. It is heavier than the OEM system and may hang lower so be a little more careful driving over speed bumps.

Right: amazingly this is the ORIGINAL Nissan muffler that came on the car back in 1998 (notice Nissan logo in the center). It has seen over 180,000 miles and has also has held up remarkably well.

Driving Impressions:

The Stromung exhaust note is quiet compared to other setups I have heard on SR20s, probably because the muffler is a quality design and there is a longer than usual resonator located directly after the cat. On a scale from 1-10, with 1 being a quiet OEM system and 10 being the loudest system you've ever heard, I'd put the Stromung at about a 4. It does not drone on the highway (the worst aspect of aftermarket exhausts IMO) and it's overall mellowness doesn't attract unwanted attention. As far as power increases I noticed a difference IMMEDIATELY above 6000 RPM. This makes sense as the motor is working it's hardest to push out as much exhaust gas as possible as the RPM increase towards redline. I didn't notice a loss of low end torque (due to the long standing debate among car enthusiasts relating to back pressure). From my knowledge of exhaust system gains on similarly modified SE-Rs, I would guess top end power increased by around 8WHP, and most likely increased power by 1-4WHP most everywhere in the power band. If my SE-R was completely stock and I bolted this exhaust up it may only gain a 2-3WHP at best. My point is this: bolt-on/breather modifications on the SR20 (and most engines) work in harmony together. One modification helps another one free more power as they work together. Camshafts may make 10WHP on a vehicle with an OEM exhaust, but put a free-flowing system on and those cams may make 14WHP or more. :-) So there's a good excuse to go get more goodies for your ride. :)

The NX2000 brake upgrade (BABK = big-ass brake kit) AD22VF conversion (The 1991 Nissan NX2000 - one of the most underrated cars ever. I have been looking for one for years but they are very rare. I gave up.)

(The 1991 Nissan NX2000 - one of the most underrated cars ever. I have been looking for one for years but they are very rare. I gave up.)The 1991-1993 NX2000 was the "sportiest" SR20DE powered vehicle available in the United States by far. Let me explin While short lived, it came with a stiffer suspension, a lower ride height, wider wheels, better slalom numbers than the B13 Sentra SE-R, and most importantly, big ass brakes! The NX2000 brakes are so good in fact, that one of the most popular modifications on the B13 Sentra SE-R & B14 200SX SE-R is to simply get the front OEM brakes from one and slap them on. The NX2000 had a much larger caliper and used a much thicker & larger rotor, which makes us wonder why Nissan didn't include this setup on the other SR20DE powered vehicles too! The stock brakes on the 91-94 Sentra SE-R and 95-98 200SX SE-R are coded as "AD18VF" while the NX2000 breaks are "AD22VF".